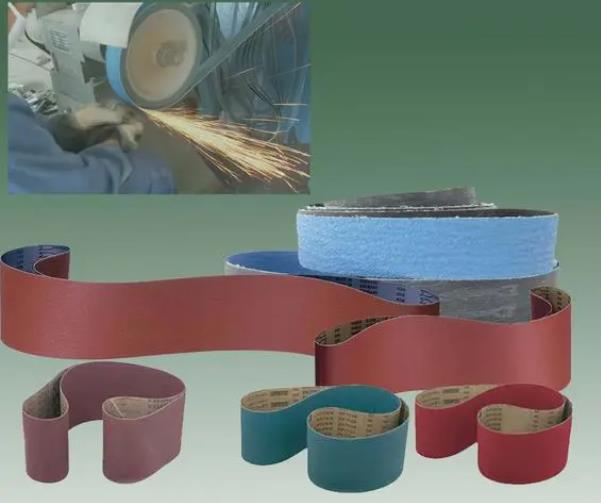

Aluminum oxide, Zirconia and Ceramic abrasive belts, which material belt is better?

If you're seeking for a new abrasive belt, you will find that you have a lot of different abrasives to choose. However, this doesn't mean that all abrasive belts are equal and all the abrasive belt are suitable for your project.

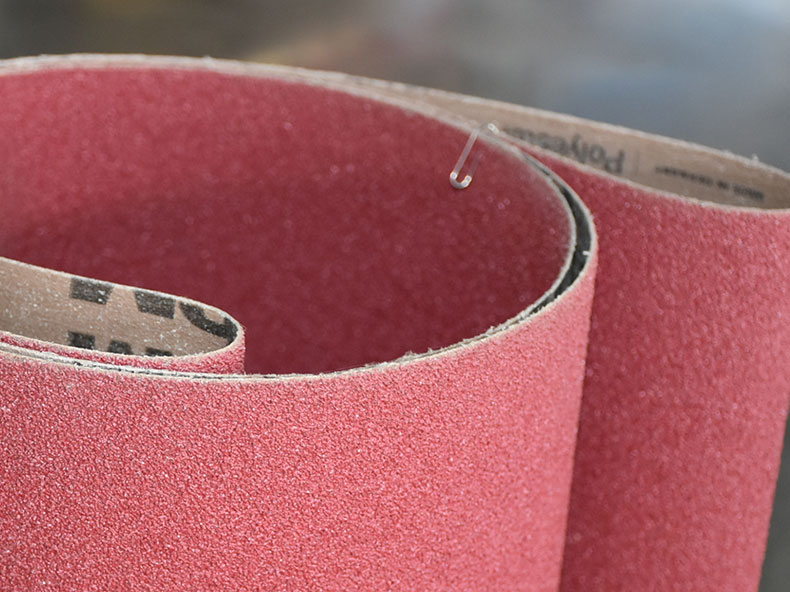

Aluminum oxide Belts:

Aluminum oxide is very popular material in the sanding world. You're likely familiar with aluminum oxide, which is the one of the most use abrasive substances. It is effective on soft and hard woods, steel and non-ferrous metals like aluminum. While it is economic, you may need a stronger abrasive for intense and prolonged steel and metal grinding.

Ceramic and zirconia are both high-performance sanding grains that have a longer service life than aluminum oxide. They also sharpen and keep doing an effective cutting job until the grain is completely worn. There is an overview of each one and how they compare to one another in performance.

Zirconia Abrasive Belts:

Zirconia grain has a high heat resistance and is stronger than aluminum oxide abrasives, which makes it a good choice for high-pressure grinding and machining applications. Zirconia belts, which work best in the 24 to 120 grit range, are regularly used in steel fabrication shops.

Although tougher than aluminium oxide, and they do a high-quality grinding job on: Stainless steel, Tool steel, Nickel alloy, Aluminum, Titanium, Cast iron, Carbon Steel, Blades, rotors, and welds.

Zirconia requires more pressure to sand, so the belts are better-suited for jobs on harder surfaces and not ideal for polishing.

Ceramic sanding belts:

Ceramic sanding belts are making a significant impact on the quality and efficiency of metal grinding applications. They are very popular in the knife industry for finishing high carbon steel. Ceramic abrasives provide the longest life and fastest cut rate out of any other type of abrasive grain. Their structure is more uniform than zirconia and they are used in a broader range of applications, including: Aluminum castings, Stainless steel finishing and Titanium alloys (commonly used in aerospace applications).

Ceramic sanding belts have a longer performance life than zirconia abrasive belt. However, unlike zirconia, ceramic is especially sensitive to pressure and heat, so their use in such applications must be carefully engineered.

Which is better?

As high-performance belts, ceramic zirconia sanding belts will last longer and remove metal faster than aluminum oxide sanding belts. All of belts have the ability to resharpen as they wear and all of them are primarily used on metal applications.

In the end, 3 types of belts are excellent belts. The decision will depend on a mixture of use and your preferences. If you need a grit higher than 120, ceramic is likely the better choice. Ceramic belts do last longer, but they are also slightly more expensive than aluminum oxide and zirconia belts. Aluminum oxide belt is more economic and zirconia belt is sharper and ideal for grinding. You should choose the proper abrasive belt according to your needs and budget.